What We Do

Our Services

System Assurance

In railway industry, RAMS is mandatory to ensure proper verification and validation through each project stages. This includes the fulfillment of EN 50126/50128/50129 standards…

What is RAMS?

RAMS stands for Reliability, Availability, Maintainability, and Safety, with the definition below,

- Reliability: ability to perform as required, without failure, for a given time interval, under given conditions. It is also considered as to be qualitative or quantitative

- Availability: ability of an item to be in a state to perform a required function under given conditions at a given instant of time or over a given time interval, assuming that the required external resources are provided

- Maintainability: ability of an item under given conditions of use, to be retained in or restored to, a state in which it can perform a required function, when maintenance is performed under given conditions and using stated procedures and resources

- Safety: freedom from unacceptable risk

Why is RAMS important?

RAMS process is a comprehensive framework used to ensure that railway systems are safe, reliable, and efficient throughout their lifecycle. It involves various analyses and assessments to mitigate potential hazards, and helps in reducing maintenance costs, ensuring high-quality service, and demonstrating the safety and reliability of the system. The most important and essential internation standards are EN50126, EN50128 (EN 50716), EN 50129.

In order to ensure an optimum maintainability of the infrastructure or rolling stock and its components the following fundamental conditions are essential:

- proven design

- the use of already proven technology

- the easy access to repair components

- inspections and overhaul pushed at their maximum

- easy installation and easy replacement during the repair process in order to reduce downtime

- innovation must be considered, either to increase or maintain quality or to reduce costs

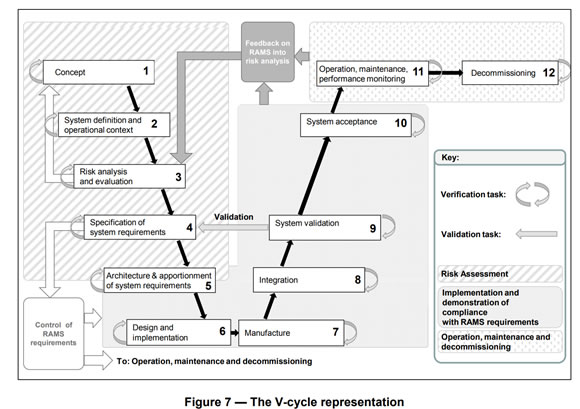

In addition to these principles, it is advisable to introduce a procedure along the V-model in accordance with EN 50126.

All steps of the V-model are to be coordinated between the contractor and the client. The continuous communication between the parties includes a validation for each step by the customer.

What do we offer to support your success?

- Specification of RAMS requirements for tenders or contracting

- Development and implementation of RAMS project and management plan

- FMEA or FMECA analysis and facilitation

- Fault tree (FTA) analysis

- FRACAS analysis

- Safety analysis and Hazard log management

- RAM studies or RAM demonstration proofs

- Safety case and RAM demonstration for Rail Systems

- Required system safety validation

- RAM performance monitoring and reporting.

Our Work

Our services are tailored to meet your specific needs and maintain a competitive edge in the market. Contact us to learn more about how we can help you and your organization achieve excellence.

Get In Touch

We believe actions speak louder than words.